Digital print

The digital printing process allows to apply individual, personalized and photorealistic print images on various substrates and article shapes (e.g. round, oval, conical, flat and square). This process allows to decorate articles with a diameter of up to 120 mm and a length of up to 450 mm. The max. print image height is 220 mm.

This contactless print process enables to print on article surfaces, which can not be decorated with the screen printing process.

Matt and glossy finish

Experience a new dimension of digital printing with digital printed drip-off. This innovative technology allows a unique combination of glossy and matt design elements together with relief effects. Perfect for packagings, which should be stick out from other designs and give an individual appearance.

With digial printed drip-off there are no limits! The combination of glossy embossing effects on a matt print, new fascinating design elements can be created. Not only for inspiring visual, but also inspiring haptical effects! Get to know our newest state of the art technology and impress your customers with unique and distinctive packagings.

Noticeable raised

Digital printed relief is a revolutionary process that enables the creation of embossing in a completely new way. Contrary to conventional processes, the digital printed relief is not made of glass. Instead, we use a special, newly developed printing process that allows for printing embossing with a height of up to 3 mm while retaining fine details and sharp contour edges.

This completely new process opens new possibilities for individual designs, which classical processes do not allow. Whether as an individual piece or a large order, digital printed relief offers cost-effective, durable solutions for the packaging industry. More than 1000 cycles on industrial dishwashing machines are no problem.

Hybrid solutions allow the combination of screen printing, digital printing, hot stamping and labeling in one machine. This flexibility opens up a variety of design possibilities. Extremely precise register tolerances and low tooling cost ensure perfect results and high profitability. Hybrid solutions offer a high degree of freedom for packaging designers and enable special effects and customized designs for individual packaging solutions.

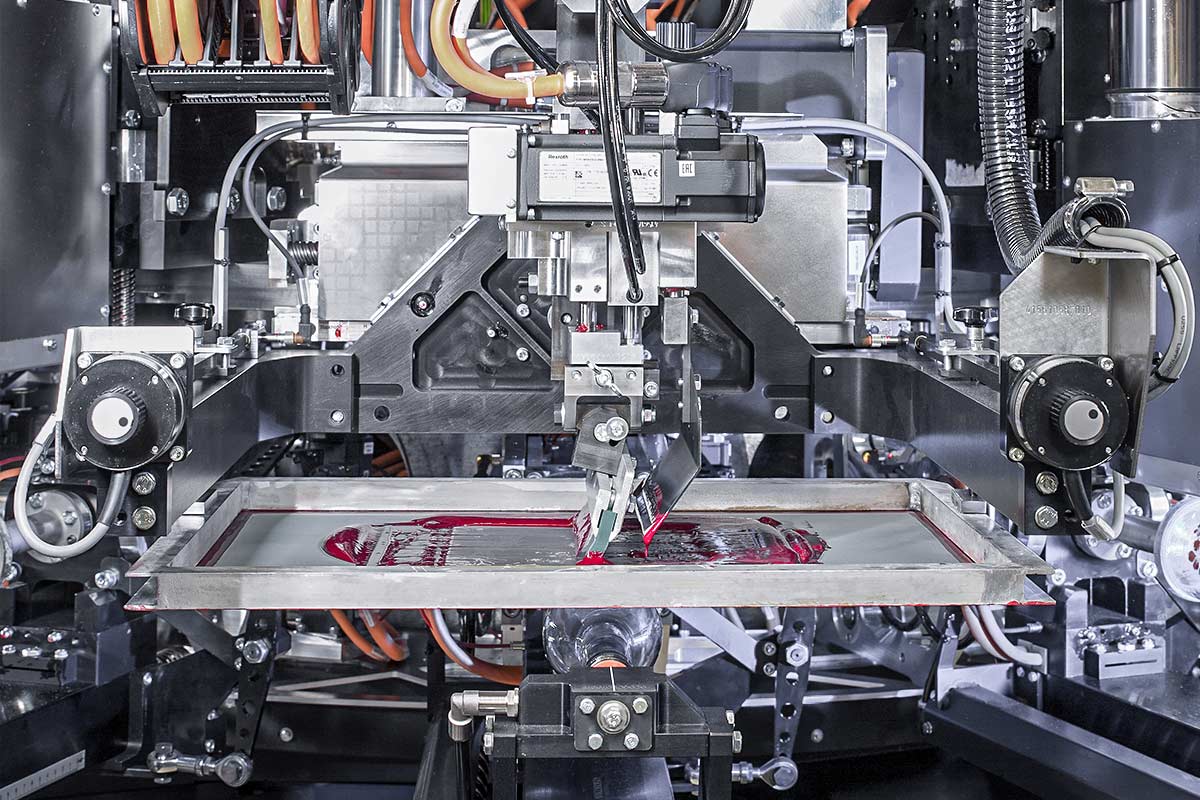

Screen printing

The screen printing process is especially in the premium segment a popular process, because of the high opacity of the colors, sharpness of the print and high level of brilliance of the print images. This process uses a rubber squeegee, which applies the printing ink through a screen to the substrate. The non printing areas a covered with a hardened photo sensitive emulsion.

Our machines can print on various materials and shapes, such as glass, ceramics and plastics. The max. printing speed is 300 articles per minute.

Hot stamping

Hot foil stamping is a process which needs time, pressure and heat to transfer a thin foil from a carrier material onto the articles by using a flat cliche or a transfer wheel. On glass articles, a primer must be applied with the screen printing process first. The primer has the exact shape of the image to be foiled – only on the primer the foil will be transferred to the substrate.

On plastic articles the application of a primer is not necessary. The plastic material of the articles allow the foil to be transferred directly by means of special transfer toolings.

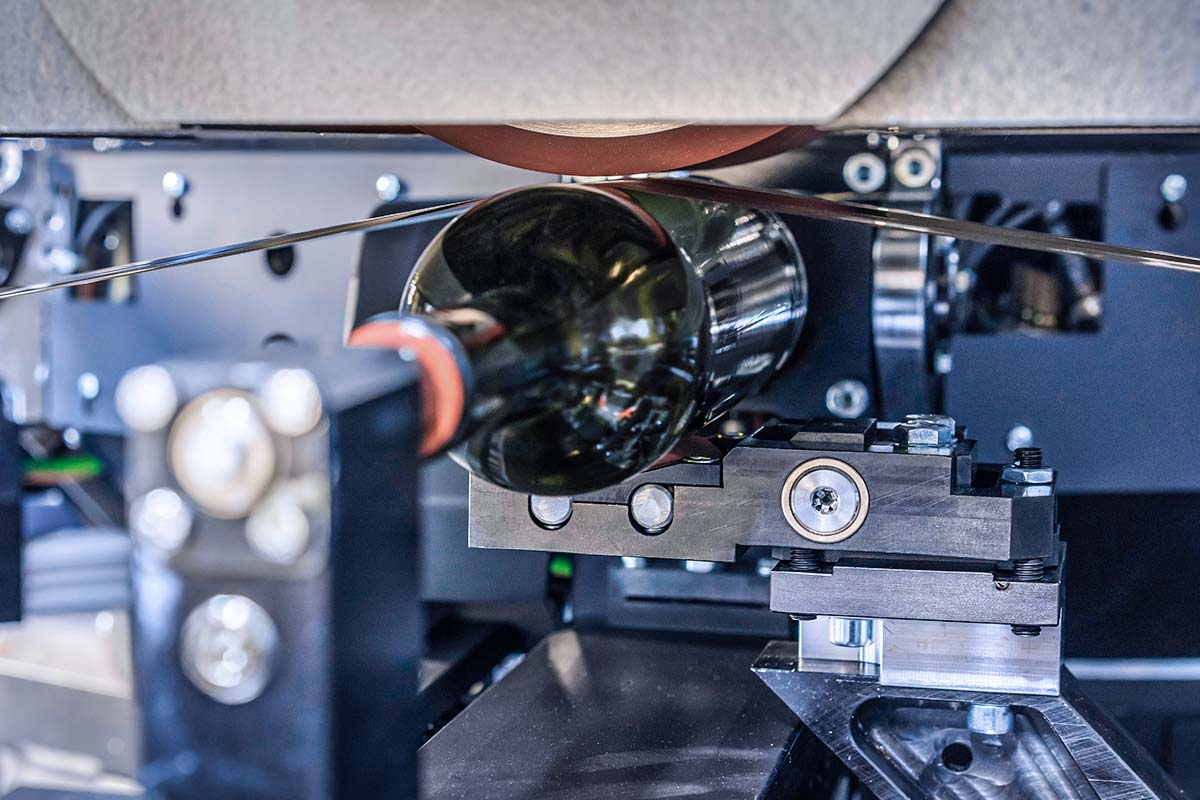

Labeling

Labeling is a decoration process, which is used to apply self-adhesive labels in one machine pass together with other processes directly on the articles. This combination with other processes offers extra flexibility and a high degree of productivity.

With the label applicator module speeds of up to 55m/min can be achieved, processing labels with a width of up to 150 mm.